|

Our products

Information

Home page

Last edited on: 2/26/23

|

Commercial industrial water filter, reverse osmosis filter, home water filter

PureWaterExpress.com (we speak English and Japanese)

P.O. Box 47, Harvard, MA 01451, founded in 1984, same location since

888-928-3794 within US, 978-456-8372 from outside US

Large Capacity Reverse Osmosis Systems

Rugged, field-tested commercial/industrial RO Systems

Free consultation with experienced water techs and engineers

Page Index

|

Commercial/Industrial RO System

Source Water Preparation for RO

Turbidity reduction

Chlorine & organics reduction

Hardness reduction

Fe, Mn & H2S reduction

Com II RO Models: 800-150 GPD

Com I RO Models: 800-150 GPD

|

VFM-Nano RO: 800 GPD

VFM RO Models: 9,000-1,500 GPD

Economy VFM RO: 9,000-1,500 GPD

WM RO Models: 4,500-450 GPD

HFM RO Models: 21,000-9,000 GPD

UV and Ozone Sterilizers

Pure Water Storage Tank

Repressurization System

Water Store Station: 6,000-1,500 GPD

|

Price levels, post sale support, warranty and policy

|

- Top of the line, highest quality US made products at competitive prices

- You benefit from factory direct delivery and personalized customer service

- Industry standard 1 year warranty on systems, longer on some components

- Beyond the factory warranty, we will cover contingencies in an equitable way

- Selection of a particular unit for any particular purpose is the buyer's responsibility

- PureWaterExpress.com is not responsibile for on-site installation, operation, maintenance, water leaks, stoppages or damages thereof, review disclaimer

|

|

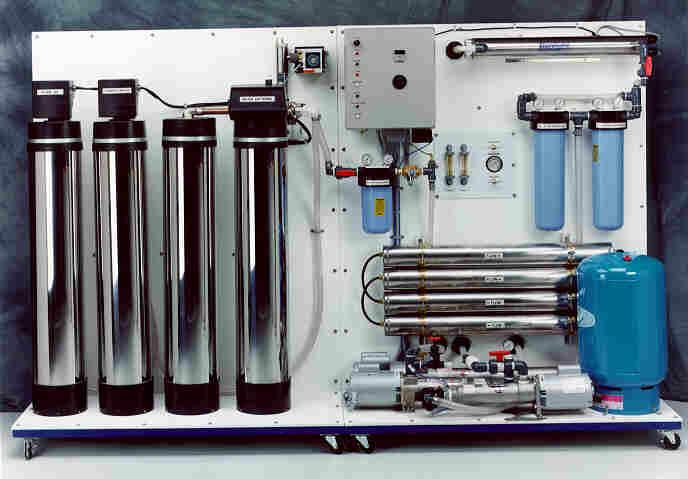

Large Capacity Commercial/Industrial RO Systems

Factory, hospital, school, restaurant, water vending store

Why should you come to PureWaterExpress.com?

- Large capacity RO system requires some serious planning, design, equipment selection and sizing

- Source water quality, application, operational environment, budget, all factors have to be weighed carefully

- Over-designing is expensive and wasteful, under-designing catastrophic

- Free access to experienced water engineers at PureWaterExpress.com and major equipment suppliers

- Factory direct delivery, full warranty, competitive pricing, post-sale customer support

- In water purification since 1984, references available upon request

Large capacity RO system composition - click for a typical layout

- Source water pre-treatment

- RO system

- Pure water storage tank(s)

- Sterilization of stored water - optional, recommended in tropical climate

- Repressurization pump

- Post filter(s) Top

Source Water Preparation for Large RO

To prevent premature membrane fouling, to increase pure water to waste water ratio

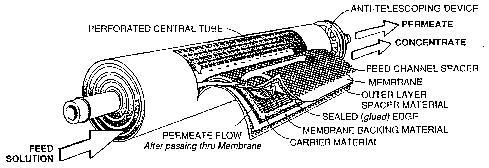

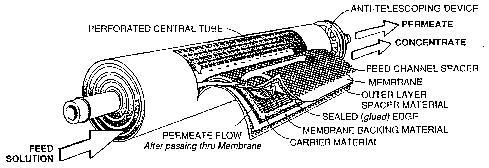

Large RO membranes are expensive, hence, most source water is pretreated so as not to foul them up ahead of their natural life. The cleaner the water, the longer the membranes will last. We then can set the pure water recovery rate that much higher, thus saving on water bills.

Source water quality requirements

-

Water temp: 85F max

- TDS: 2,000 ppm max

- Iron tolerance: 0.5 ppm max

- Hydrogen sulfide: must be removed

- Silica tolerance: less than 125 ppm, antiscalant should be considered for over 75 ppm

- Turbidity: must be removed

- Hardness: over 10 gpg should be softened

- pH range: 3-11

A source water analysis is recommended before considering a commercial/industrial RO system.

We can help you pretreat water for most conditions as discussed below. The throughput capacity of the pretreatment equipment must be sufficient to adequately filter the sum total of the permeate flow (RO GPD rating) and the anticipated waste water flow into drain.

At lower source water temperatures of less than 77F (25C), actual RO production will be less than the system GPD rating. To estimate the actual production, GPD rating has to be divided by 1.19 at 68F (20C), by 1.47 at 59F (15C), by 1.89 at 50F (10C), by 2.58 at 41F (5C). The temperature derating effect must be included in your system design consideration.

Top

Turbidity Reduction - removal of rock, sand, dirt, rust particles

Turbo-clean, auto-flush mesh screen type sediment filter - 140F water temperature and 150 psi rated

|

|

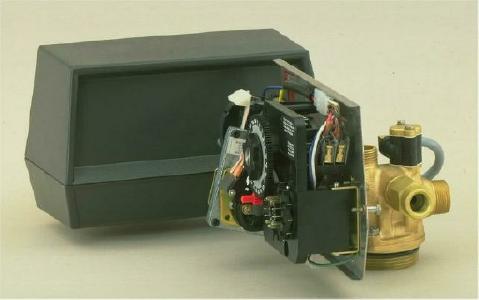

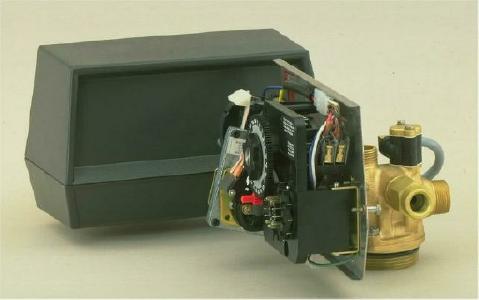

Model TAF-750E, 3" or 2" turbo-clean, electric auto-flush sediment filter

- Electricity is required, 110 volts 60 hz standard, 220 volts 50-60 hz available

- Electronic timer operates hydraulic auto flush valve, purges accumulated dirt

- Programming allows the flush cycle from once every 5 minutes to seven days

- Standard coupling is 3" flange or 2" male pipe thread for inlet/outlet

- 3" unit max 220 gallons per minute (gpm), 2" unit max 110 gpm

- Available mesh sizes are, 500, 300, 200, 130, 100, 80 and 50 microns

- Mesh size has to match water condition, you may have to try a few meshes

- Some people string two units in row with coarse and fine mesh sizes

Cost for 2" turbo-clean, auto-flush sediment filter

- 2" unit supports 110 GPM flow and fits within 12" w. x 26" h. x 7.4" d. space envelope

- Please contact us for price, 1-888-928-3794 in US, 1-978-456-8372 from outside US

|

Model TAF-500H, 3" or 2" turbo-clean, hydraulic auto-flush sediment filter

- 110 volts AC not required, programmable timer operates on internal battery

- Electronic timer operates hydraulic auto flush valve, purges accumulated dirt

- Programming allows the flush cycle from once every 5 minutes to seven days

- Standard coupling is 3" flange or 2" male pipe thread for inlet/outlet

- 3" unit max 220 gallons per minute (gpm), 2" unit max 110 gpm

- Available mesh sizes are, 500, 300, 200, 130, 100, 80 and 50 microns

- Mesh size has to match water condition, you may have to try a few meshes

- Some people string two units in row with coarse and fine mesh sizes

Cost for 2" turbo-clean, auto-flush sediment filter

- 2" unit supports 100 GPM flow and fits within 22" x 14" x 7.4" space envelope

- Please contact us for price, 888-928-3794 within US, 978-456-8372 from outside US

Top

|

|

|

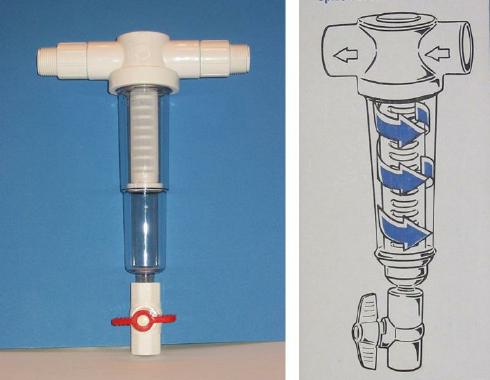

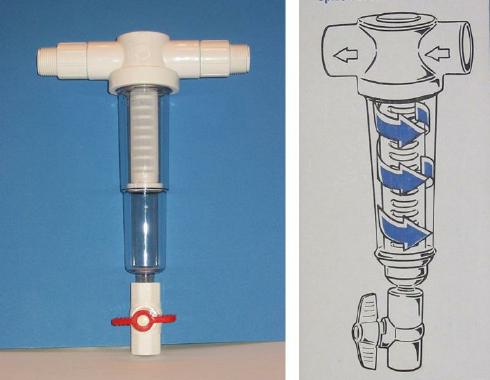

Manual-clean transparent bowl mesh screen type sediment filter - removal of simple turbidity

Spindown sediment removal

|

|

Easy to see and flush, washable mesh filter lasts forever

Mesh screen in a chemical resistant transparent bowlWater swirls down and keeps the mesh screen cleanCoarse mesh sizes made of stainless, fine mesh polyester Flush out sediment with a flick of the drain valve

Can be taken apart, washed, the unit lasts indefinitelyRated for 120F water temp and 150 psi

Slip connection of up to 2"

2" unit supports 100 GPM flow, 1-1/2" 50 GPM and 1" 20 GPM

Screens: 24 mesh (711 microns), 30 (533), 40 (381), 60 (254), 100 (152), 140 (104), 250 (61), 500 (30) and 1,000 (15)You may have to try a few different sizes to match water

If too fine, it plugs up, if too coarse, not much filteringSome install a few units in a row with different mesh sizes

|

Cost

Please contact us for price, 888-928-3794 within US, 978-456-8372 from outside US

Top

Washable bag sediment filter - works like a vacuum cleaner, washable (or disposable) bag traps dirt

|

|

Wholehouse FSI-X100 unit 8" diam, 2-1/2 ft tall, 2" FPT

Meets ASME code requirements

Bag is 6" diam 20" long

Bag is washable or disposable, good to have a few on hand

Lid holds down bag, special design eliminates need for gaskets

Choose from pore size 50, 25, 10, 5 and 1 micron

Housing option: carbon steel, 304 or 316 stainless, titanium or hastelloy

Call for price at 888-928-3794 within US, 978-456-8372 from outside US

Top

|

|

Mechanism

|

Multi Media Sediment Filter - removal of multi-constituent high value complex turbidity

Unit price, loaded, ready to install

Capacity in

cubic foot | Tank

diam/tall | Fleck

valve | Service

flow rate | Backwash

flow rate | Complete

unit price | Ship

wgt |

| 17.6 | 36"/72" | 3150 | 69 GPM | 85 GPM | | lbs |

| 12.5 | 30"/72" | 3150 | 48 GPM | 60 GPM | | lbs |

| 8.0 | 24"/72" | 2850 | 30 GPM | 40 GPM | | lbs |

| 6.0 | 21"/69" | 2850 | 24 GPM | 30 GPM | | lbs |

| 4.4 | 18"/65" | 2750 | 18 GPM | 25 GPM | | lbs |

RO GPD capacity plus the expected waste flow determine the recommended volume

Requires robust backwash flow rate to keep the media clean, see table

Multi media can be washed/regenerated with Clorox

Please call us for prices at 888-928-3794 within US, 978-456-8372 from outside US Top

Loose Granular Carbon for Chlorine and Organic Chemical Reduction

The more chemicals carbon removes, the longer the membrane will last

Backwash carbon filter

|

Fleck backwash control

2750 valve

Click to order

|

What it does

Reduces chlorine, odor, tri-halo methane THM, gas additive MTBE, and organic pollutants such as EDB, PCB, benzene and TCE

Protects TFC RO membrane

Hard water should be additionally softened

|

Unit price, loaded and ready to install

Capacity in

cubic foot | Tank

diam/tall | Fleck

valve | Service

flow rate | Backwash

flow rate | Complete

unit price | Ship

wgt |

| 17.6 | 36"/72" | 3150 | 42 GPM | 70 GPM | | lbs |

| 12.5 | 30"/72" | 3150 | 29 GPM | 50 GPM | | lbs |

| 8.0 | 24"/72" | 2850 | 19 GPM | 30 GPM | | lbs |

| 6.0 | 21"/69" | 2850 | 14 GPM | 25 GPM | | lbs |

| 4.4 | 18"/65" | 2750 | 11 GPM | 20 GPM | | lbs |

Supply flow rate requirement for the RO unit(s) determines the carbon filter size

Must process the sum of the particular GPD RO permeate flow plus projected waste flow

Please call us for prices at 888-928-3794 within US, 978-456-8372 from outside US

Top

Hardness Reduction - twin tank (duplex) softener for mineral removal at all times

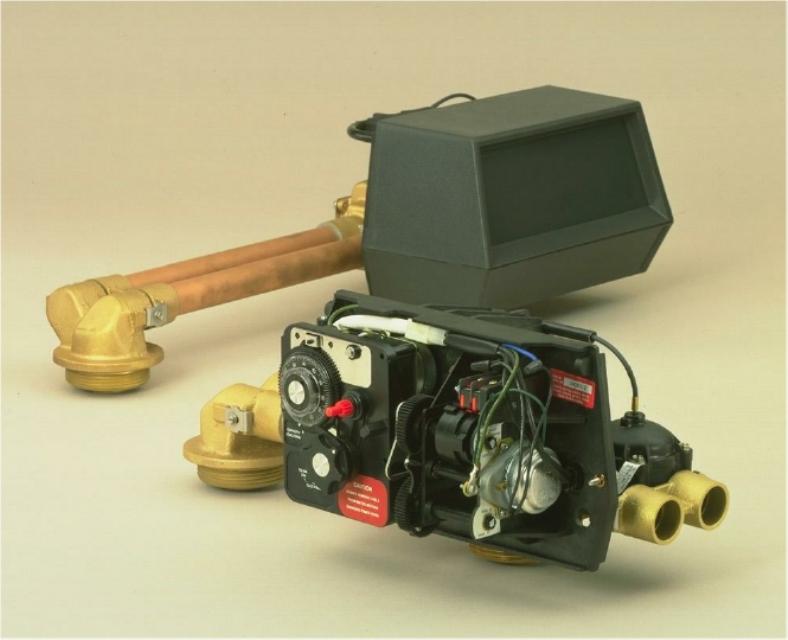

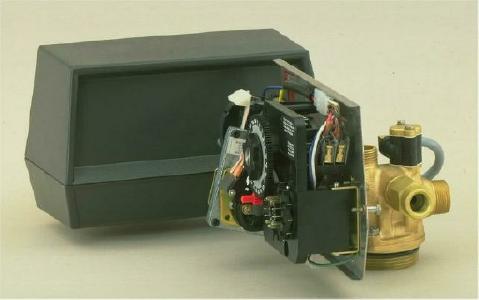

Twin alternating tank (duplex) softener #9000 valve

|

|

Fleck #9000 valve, 1" bypass

|

What it does

Water softener removes excess minerals which foul up RO membranesTwin tank alternating backwash means water going through is softened (and RO can operate) at all times

Hardness, TDS and RO GPD determine the softener size, generally the larger the better

Calender clock backwash takes place at a preprogrammed interval

Single tank softener also available, less expensive but lockout logic must disable RO while softener is regenerating

Calender duplex clock, loaded and ready to install - other sizes not listed below are available, please call for prices

Capacity in

cubic foot | Twin tanks

diam/tall | Brine tank

diam/tall | Fleck

valve | Pipe

size | Critical

flow rate | -15 psi

flow rate | -25 psi

flow rate | Backwash

flow rate | Complete

unit price |

| 36 | 48"/72" | 50"/60" | 3900 | 3" | 180 GPM | 205 GPM | 278 GPM | 60 GPM | |

| 26 | 42"/72" | 42"/60" | 3900 | 3" | 130 GPM | 197 GPM | 266 GPM | 45 GPM | |

| 20 | 36"/72" | 42"/60" | 3900 | 3" | 100 GPM | 84 GPM | 111 GPM | 36 GPM | |

| 15 | 30"/72" | 39"/48" | 2900 | 2" | 75 GPM | 73 GPM | 105 GPM | 25 GPM | |

| 10 | 24"/72" | 30"/50" | 2900 | 2" | 38 GPM | 38 GPM | 51 GPM | 15 GPM | |

| 6 | 21"/54" | 24"/50" | 2900 | 2" | 30 GPM | 39 GPM | 50 GPM | 12 GPM | |

| 3 | 14"/65" | 24"/50" | 2900 | 2" | 15 GPM | 29 GPM | 41 GPM | 5 GPM | |

Top

Chem-Free Iron Reduction Filter - Most effective for removing iron

Natural vessel

|

|

2750 valve

|

What it does

Attention-free operation

removes iron concentrations

of up to 35 ppm

Removes soluble ferrous "clear water" iron,

precipitated ferric "red

water" iron, and bacterial iron

Specify A-type media for alkaline water (pH of 7 and above), AM-type media for acidic water (pH less than 7)

System performance will benefit from inclusion of aerator and vent combination

Always recommend water analysis by independent lab before ordering

Five year warranty on Fleck

NorylŪ control valve, 10 year warranty on heavy duty mineral tanks

No chemical regeneration required, nothing is imparted into the house water

Complete unit - we support installation with diagrams and live phone calls

Capacity in

cubic foot | Tank

diam/tall | Fleck

valve | Service

flow rate | Backwash

flow rate | Complete

unit price | Ship

wgt |

| 17.6 | 36"/72" | 3150 | 32 GPM | 70 GPM | | lbs |

| 12.5 | 30"/72" | 3150 | 22 GPM | 50 GPM | | lbs |

| 8.0 | 24"/72" | 2850 | 14 GPM | 30 GPM | | lbs |

| 6.0 | 21"/69" | 2850 | 11 GPM | 25 GPM | | lbs |

| 4.4 | 18"/65" | 2750 | 8 GPM | 20 GPM | | lbs |

| 3.5 | 16"/65" | 2750 | 6 GPM | 16 GPM | | lbs |

Top

Birm Filter - iron and manganese reduction

Complete unit - we support installation with diagrams and live phone calls

Capacity in

cubic foot | Tank

diam/tall | Fleck

valve | Service

flow rate | Backwash

flow rate | Complete

unit price | Ship

wgt |

| 17.6 | 36"/72" | 3150 | 32 GPM | 70 GPM | | lbs |

| 12.5 | 30"/72" | 3150 | 22 GPM | 50 GPM | | lbs |

| 8.0 | 24"/72" | 2850 | 14 GPM | 30 GPM | | lbs |

| 6.0 | 21"/69" | 2850 | 11 GPM | 25 GPM | | lbs |

| 4.4 | 18"/65" | 2750 | 8 GPM | 20 GPM | | lbs |

| 3.5 | 16"/65" | 2750 | 6 GPM | 16 GPM | | lbs |

Top

Filox-R Filter - non-chemical removal of Fe, Mn and H2S

What it does

Alamo-brand Filox-R (click for media detail) for iron, manganese and/or hydrogen sulfide reduction

No chemical regeneration required, nothing is imparted into the house water or drain

Thin oxidized layer forms on the media surface, gets scrubbed away during backwash cycle

Incoming water pH range of (6.5-9.0) for optimum results, not greasy, organic matters of less than 5 ppm

Optimum operation by adding aerator-vent combination

Media seen to last several years when adequately backwashed, can be cleaned up with Clorox if get greasy or dirty

Complete unit - we support installation with diagrams and live phone calls

Capacity in

cubic foot | Tank

diam/tall | Fleck

valve | Service

flow rate | Backwash

flow rate | Complete

unit price | Ship

wgt |

| 8.0 | 24"/72" | 3150 | 48 GPM | 50 GPM | | lbs |

| 6.0 | 21"/69" | 2850s | 24 GPM | 36 GPM | | lbs |

| 4.4 | 18"/65" | 2850s | 26.5 GPM | 30 GPM | | lbs |

| 3.5 | 16"/65" | 2750 | 21 GPM | 25 GPM | | lbs |

Fe, Mn and/or H2S levels and RO GPD determine the recommended pyrolox volume, the larger the better

Requires consistent supply water flow with pressure of 40-60 psi for vigorous backwash

Top

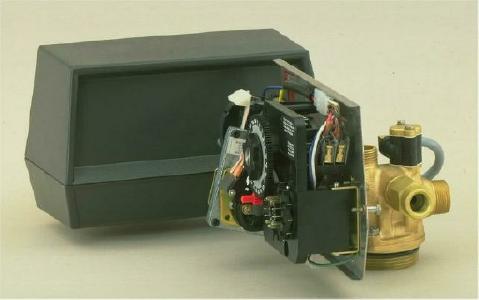

Com II Model Reverse Osmosis System - 800 GPD, 450, 250 and 150

Com II RO

|

|

What it does

Works with chlorinated municipal water or well water

Prefilters: Slimline (2-1/4" dia x 20" long) sediment and carbon

TFC membrane at 200 psi, 95-99% salt rejection

One year factory warranty

Stainless housing, powder-coated steel bracket

Feed water solenoid valve, high pressure brass fittings and nylon tubing

Inlet/outlet pre-filter gauges, liquid filled system gauge

Additional pressure gauge for sealed storage tank

Adjustable waste/recycle flow controls, optimum water recovery

Storage tank pressure switch, low pressure safety switch

Rotary vane pump, 3/4 hp motor (COM II-4), 1/2 hp motor (COM II-3-2-1)

Straightforward installation, simple operation

Compact design with highest quality US components, needs minimal space

|

Unit selection consideration

Source water analysis is recommended prior to unit selection

Depending on source water quality you may require additional pre-treatment such as anti-scalant filter, neutralizer

You need storage tank, either bladder type or open air tank with pressure booster pump

Free discussion at 888-928-3794 within US, 978-456-8372 from outside US, also for current prices

Dimensions

| Model | Minimum

GPD | Membrane | Piping

inlet / waste / prod | Size/weight |

| Com II-4 | 850 | 4" dia x 21" long, 1 each | 1/2" 3/8" 3/8" | 14" x 16" x 30" tall, 95 lbs |

| Com II-3 | 475 | 4" dia x 14" long, 1 each | 3/8" 3/8" 3/8" | 14" x 16" x 30" tall, 92 lbs |

| Com II-2 | 275 | 2.5" dia x 21" long, 1 each | 3/8" 3/8" 3/8" | 14" x 16" x 30" tall, 88 lbs |

| Com II-1 | 175 | 2.5" dia x 14" long, 1 each | 3/8" 3/8" 3/8" | 14" x 16" x 30" tall, 85 lbs |

Source water pre-treatment, available options

Additional pre-treatment should be provided in front of the 800 and 450 GPD units for membrane protection

The built-in pre-filtration is sufficient for the 250 and 150 GPD models

Stainless pump, stainless membrane housing, stainless needle valves, product and waste flow meters

Automatic (hourly) or manual flush, 220 volt pump motor, float switch for atmospheric tank, pretreatments

Top

Com I Model Reverse Osmosis System - 800 GPD, 450, 250 and 150

| What it does

Works with chlorinated municipal water or well water

Prefilters: two Big Blue Short (4-1/2" x 10") carbons, one sediment

TFC RO membrane operating at 200 psi, 95-99% salt rejection

One year factory warranty

Water storage tank and repressurization pump are not included

Straightforward installation, simple operation

Compact design with highest quality US components

Inlet/outlet pre-filter gauges, liquid filled system gauge

Storage tank pressure switch, low pressure safety switch

Feed water inlet solenoid valve

Rotary vane pump, 3/4 hp motor (COM I-4), 1/2 hp (COM I-3-2-1)

Stainless steel fixed waste and recycle flow controls

|

|

|

Dimensions

| Model | Minimum

GPD | Membrane | Piping

inlet / waste / prod | Size/weight |

| Com I-4 | 850 | 4" dia x 21" long, 1 each | 1/2" 3/8" 3/8" | 26" x 16" x 18" tall, 74 lbs |

| Com I-3 | 475 | 4" dia x 14" long, 1 each | 3/8" 3/8" 3/8" | 21" x 16" x 18" tall, 72 lbs |

| Com I-2 | 275 | 2.5" dia x 21" long, 1 each | 3/8" 3/8" 3/8" | 26" x 16" x 18" tall, 68 lbs |

| Com I-1 | 175 | 2.5" dia x 14" long, 1 each | 3/8" 3/8" 3/8" | 21" x 16" x 18" tall, 65 lbs |

Source water pre-treatment, available options

Additional pre-treatment should be provided in front of the 800 and 450 GPD units for membrane protection

The built-in pre-filtration is sufficient for the 250 and 150 GPD models

Stainless pump, stainless membrane housing, stainless needle valves, product and waste flow meters

Automatic (hourly) or manual flush, 220 volt pump motor, float switch for atmospheric tank, pretreatments

Call us at 888-928-3794 in US, 978-456-8372 from outside US, we offer free consultation on model/size selection

Top

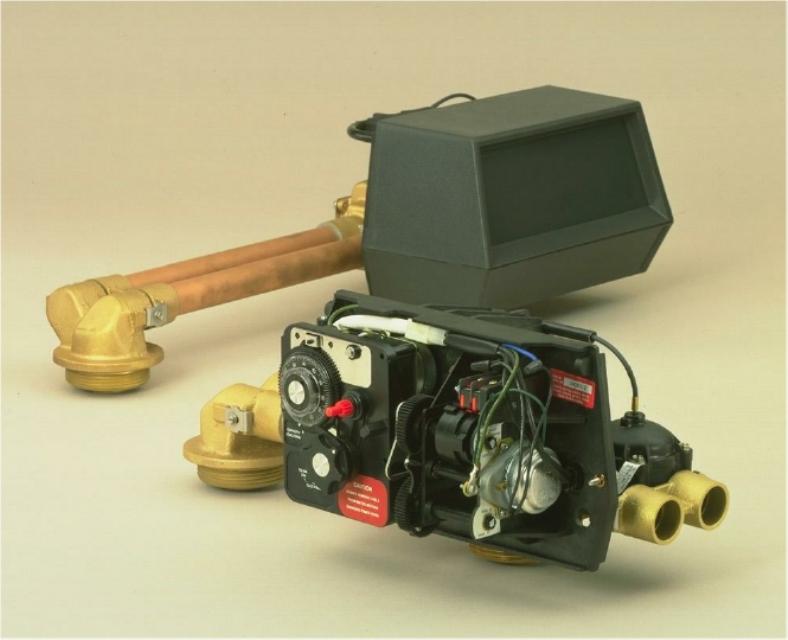

WM Model RO - 4,500 GPD, 3,000, 1,500

Wall mounted RO

|

|

What it does

Wall mounted frame, powder-coated steel frame, rust resistant

TFC RO membrane operating at 200 psi, 95-99% salt rejection

One year factory warranty

Stainless multi-stage pump (WM-5 through WM-3)

1/2 HP rotary vane pump (WM-2 & WM-1)

Fiberglass wall mount panel, PVC membrane housing, high pressure tubing

Inlet/outlet pre-filter gauges, liquid filled system gauge

Adjustable stainless waste/recycle needle valve (WM-5 through WM-2)

Fixed stainless waste/recycle flow control (WM-1 only)

Feed water solenoid valve, designed for optimum water recovery

Product and waste flow meters (WM-5 through WM-2)

Pure water storage tank nor repressurization pump included

Compact design, highest quality US components, minimal space

Straightforward installation, simple operation

|

Dimensions

| Model | Minimum

GPD | Membrane | Piping

inlet / waste / prod | Size/weight |

| WM-3 | 5,000 | 4" dia x 40" long, 3 each | 3/4" 1/2" 1/2" | 32" x 15" x 52" tall, 200 lbs |

| WM-2 | 3,600 | 4" dia x 40" long, 2 each | 3/4" 1/2" 1/2" | 28" x 15" x 52" tall, 175 lbs |

| WM-1 | 2,000 | 4" dia x 40" long, 1 each | 3/4" 1/2" 1/2" | 28" x 15" x 52" tall, 150 lbs |

Available options at added cost

Stainless membrane housing, stainless needle valves (WM-3 thru WM-1)

Automatic (hourly) or manual flush, 220 volt pump motor, 50 Hz

Digital or analog TDS monitor, hour meter, recycle flow meter, tank pressure switch, product diversion

IEC contactor with overload, pre-treat lock-out with light pretreatments

Top

Economy Vertical Frame Mounted RO - 10,000 GPD, 8,000, 6,500, 5,000, 3,600 and 2,000

Eco VFM RO

|

|

What it does

Brand new model, emphasis on functionality and durability over fancy looks

TFC RO membrane operating at 200 psi, 95-99% salt rejection

One year factory warranty

Stainless steel multi-stage Webtrol pump, fused motor circuit

Electrical control junction box with on/off safety switch

PVC membrane housing, powder-coated steel bracket

High pressure brass fittings and nylon tubing

Liquid filled system gauge

Adjustable stainless waste needle valve

Adjustable dual level float switch, low pressure safety switch

Feed water inlet solenoid valve

Neither pure water storage tank nor repressurization pump included

Straightforward installation, simple operation

Compact design, highest quality US components, minimal space

|

Dimensions

| Model | Minimum

GPD | Membrane | Pump | Piping

inlet / waste / prod | Dimensions |

| Eco-VFM-6 | 10,000 | 4" dia x 40" long, 6 each | multi-stage 3 hp | 1" 1/2" 1/2" | 17" x 16" x 52" tall |

| Eco-VFM-5 | 8,000 | 4" dia x 40" long, 5 each | multi-stage 3 hp | 1" 1/2" 1/2" | 17" x 16" x 52" tall |

| Eco-VFM-4 | 6,500 | 4" dia x 40" long, 4 each | multi-stage 3 hp | 1" 1/2" 1/2" | 17" x 16" x 52" tall |

| Eco-VFM-3 | 5,000 | 4" dia x 40" long, 3 each | multi-stage 2 hp | 1" 1/2" 1/2" | 17" x 16" x 52" tall |

| Eco-VFM-2 | 3,600 | 4" dia x 40" long, 2 each | multi-stage 2 hp | 1" 1/2" 1/2" | 17" x 16" x 52" tall |

| Eco-VFM-1 | 2,000 | 4" dia x 40" long, 1 each | multi-stage 1 hp | 3/4" 1/2" 1/2" | 17" x 16" x 49" tall |

Available options at added cost

Product and waste flow meters, recycle valve (requires waste flow meter in place)

Pressure gauges before and after pre-filter, stainless membrane housings

Manual flush, 50 Hz conversion, tank pressure switch

Top

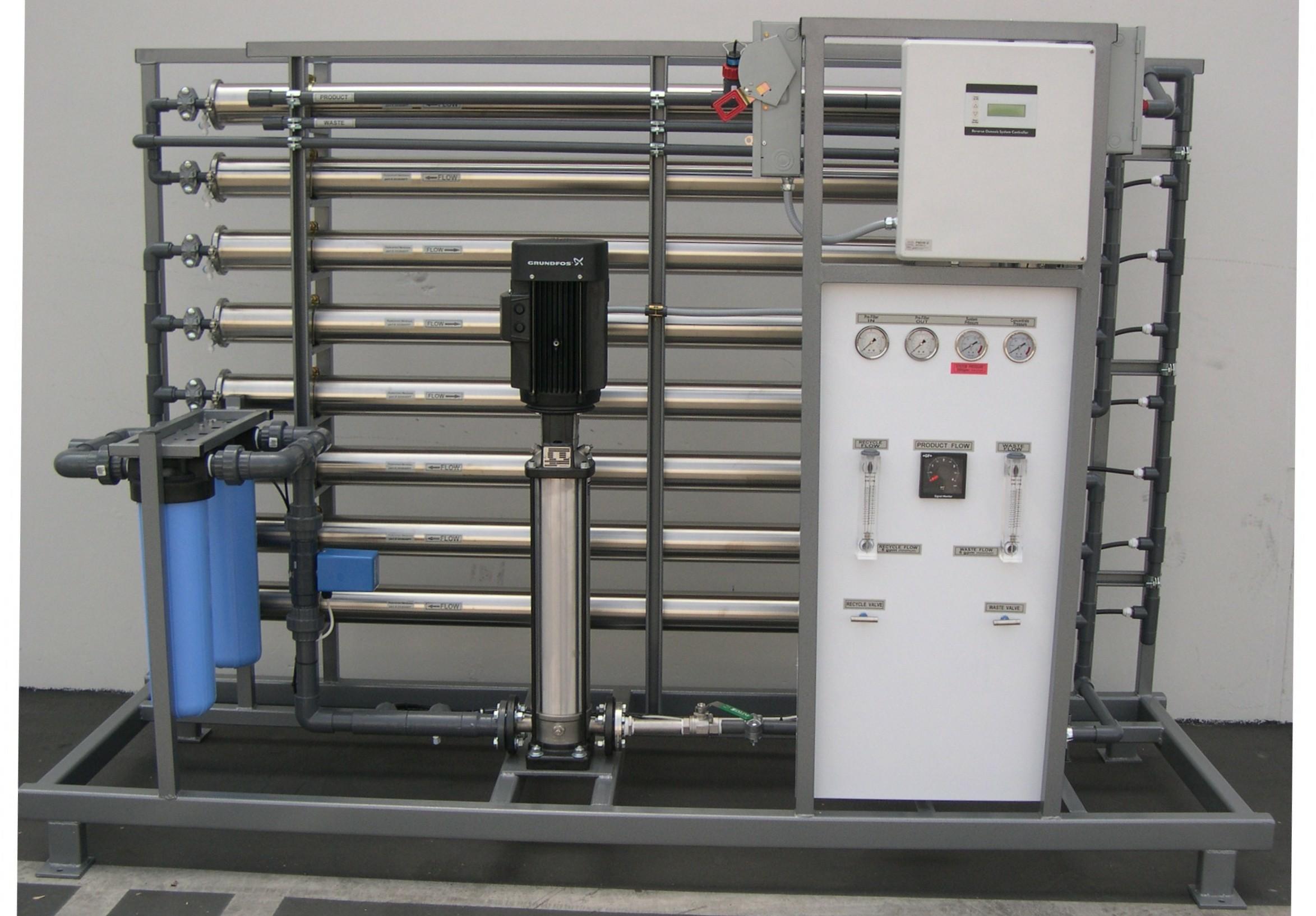

Vertical FM Model RO - 10,000, 8,000, 6,500, 5,000, 3,600, 2,000 GPD minimum

| What it is and does

Floor standing model, durable powder-coated frame

TFC RO membrane operating at 200 psi, 95-99% salt rejection

Standard unit uses Fluid Systems TFC membrane(s) 1,800 GPD each

One year factory warranty

PVC membrane housing standard, stainless option as shown

Liquid filled high pressure gauge, inlet/outlet pre-filter gauges

Adjustable waste/recycle needle valves

Product and waste flow meters, designed for optimum water recovery

Dual level tank switches, low pressure safety switch

Feed water solenoid valve, stainless steel multi-stage pump

Straightforward installation, simple operation

Compact design, highest quality US components, minimal space

Source water test/analysis is recommended

|

|

V-FN RO

|

Dimensions

| Model | Minimum

GPD | Membrane | Pump | Piping

inlet / waste / prod | Dimensions |

| V-FM-6 | 10,000 | 4" dia x 40" long, 6 each | multi-stage 3 hp | 1" 1/2" 1/2" | 29" x 29" x 61" tall |

| V-FM-5 | 8,000 | 4" dia x 40" long, 5 each | multi-stage 3 hp | 1" 1/2" 1/2" | 29" x 29" x 61" tall |

| V-FM-4 | 6,500 | 4" dia x 40" long, 4 each | multi-stage 3 hp | 1" 1/2" 1/2" | 29" x 29" x 61" tall |

| V-FM-3 | 5,000 | 4" dia x 40" long, 3 each | multi-stage 2 hp | 1" 1/2" 1/2" | 29" x 29" x 61" tall |

| V-FM-2 | 3,600 | 4" dia x 40" long, 2 each | multi-stage 2 hp | 1" 1/2" 1/2" | 24" x 29" x 57" tall |

| V-FM-1 |

2,000 | 4" dia x 40" long, 1 each | multi-stage 1 hp | 3/4" 1/2" 1/2" | 24" x 29" x 57" tall |

Top

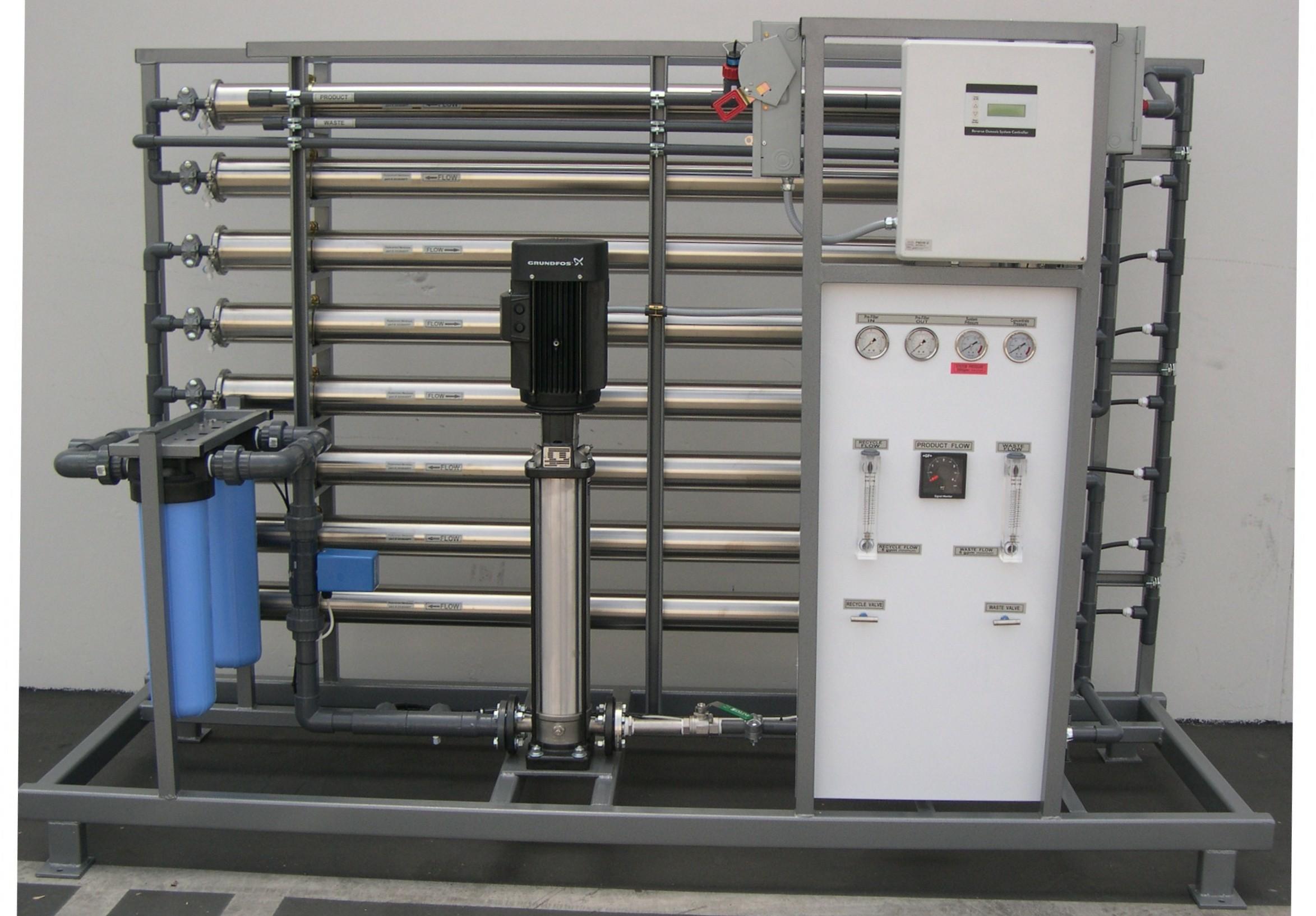

Horizontal FM Model RO - 24,000 GPD, 21,000, 17,,000, 13,700, 10,500

| What it does

TFC RO membrane at 200 psi, 95-99% salt rejection

One year factory warranty

Source water test/analysis is recommended

Skid mounted, durable powder-coated steel frame

PVC membrane housing, high pressure brass fittings

Inlet/outlet pre-filter and liquid filled system gauges

Adjustable stainless waste/recycle fixed flow control

Membrane at 200 psi, optimum water recovery

Dual level tank switches, low pressure safety switch

Dependable relay logic safety and control circuit

Stainless steel multi-stage centrifugal pump

Sampling valves to monitor each membrane vessel

Compact design, highest quality US components

|

|

H-FM RO

|

Unit design

At this level total system design is absolutely necessary, RO water production requirements, cost objective

Rigorous source water test comes first, which leads to pre-RO source water treatment ensemble

Neither source water pretreatment equipment nor post RO pure water storage/repressurization included

We have numerous large RO system clients over the 39 years, please contact us

Dimensions

| Model | Minimum

GPD | Membrane | Pump | Piping

inlet / waste / prod | Dimensions |

| H-FM-14 | 24,000 | 4" dia x 40" long, 14 each | 7.5 hp | 1-1/2" 1" 1" | 110" x 31" x 66" tall |

| H-FM-12 | 21,000 | 4" dia x 40" long, 12 each | 7.5 hp | 1-1/2" 1" 1" | 110" x 31" x 66" tall |

| H-FM-10 | 17,000 | 4" dia x 40" long, 10 each | 7.5 hp | 1-1/2" 1" 1" | 110" x 31" x 66" tall |

| H-FM-8 | 13,700 | 4" dia x 40" long, 8 each | 5 hp | 1-1/2" 1" 1" | 110" x 31" x 66" tall |

| H-FM-6 | 10,500 | 4" dia x 40" long, 6 each | 5 hp | 1-1/2" 1" 1" | 110" x 31" x 66" tall |

Top

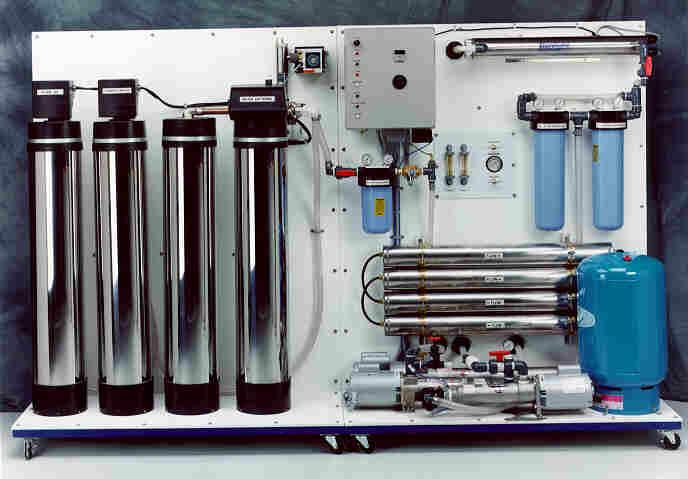

Full Water Store Station - 6,000 GPD, 4,500, 3,000, 1,500

| What it does - complete RO water store station on wheels

Chlorinated municipal water or well water

TFC membrane at 200 psi, 95-99% salt rejection

Two 1.5 cubic foot carbon filter with auto backwash

1.5 cubic foot twin tank softener, auto backwash

Stainless multi-stage pump for durability

TFC RO membrane, PVC membrane housing

Powder-coated steel bracket, two skids joined

Two 300 gallon water storage tanks (not shown)

Stainless repressurization pump w/10 gallon tank

Two 20" Big Blue carbon block post filters

Stainless 24 GPM UV water sterilizer

|

|

Complete water store station

(two 300 gallon each tanks not shown)

|

Adjustable stainless waste/recycle fixed flow control

Inlet/outlet pre-filter gauges, liquid filled system gauge

One year factory warranty, designed for optimum water recovery

Storage tank pressure switch, low pressure safety switch, feed water solenoid valve

Dimensions

| Model | Minimum GPD | Number of membranes | Pump | Two demountable skids | Weight |

| FS-4 | 7,200-6,000 | 4" dia x 40", 4 each | 3 hp | 110" w, 31" d, 66" h | 1,800 lbs. |

| FS-3 | 5,400-4,500 | 4" dia x 40", 3 each | 2 hp | 110" w, 31" d, 66" h | 1,800 lbs. |

| FS-2 | 3,600-3,000 | 4" dia x 40", 2 each | 2 hp | 110" w, 31" d, 66" h | 1,800 lbs. |

| FS-1 | 1,800-1,500 | 4" dia x 40", 1 each | 1 hp | 110" w, 31" d, 66" h | 1,800 lbs. |

Top

Other pages:

Whole house filter - Drinking water filter - How to order - FAQ

About us

|

PureWaterExpress.com, owned by

Prosperity Management, Inc.

E-mail (Japanese OK): sales@purewaterexpress.com

Tel: 888-928-3794 (888-water-94) toll-free US

978-456-8372

outside US,

Fax: 978-456-6975

P.O. Box 47, Harvard, MA 01451 (same location

since 1984)

|

Home page

|

Copyright 1999: Prosperity Management,

Inc., Massachusetts corporation

|